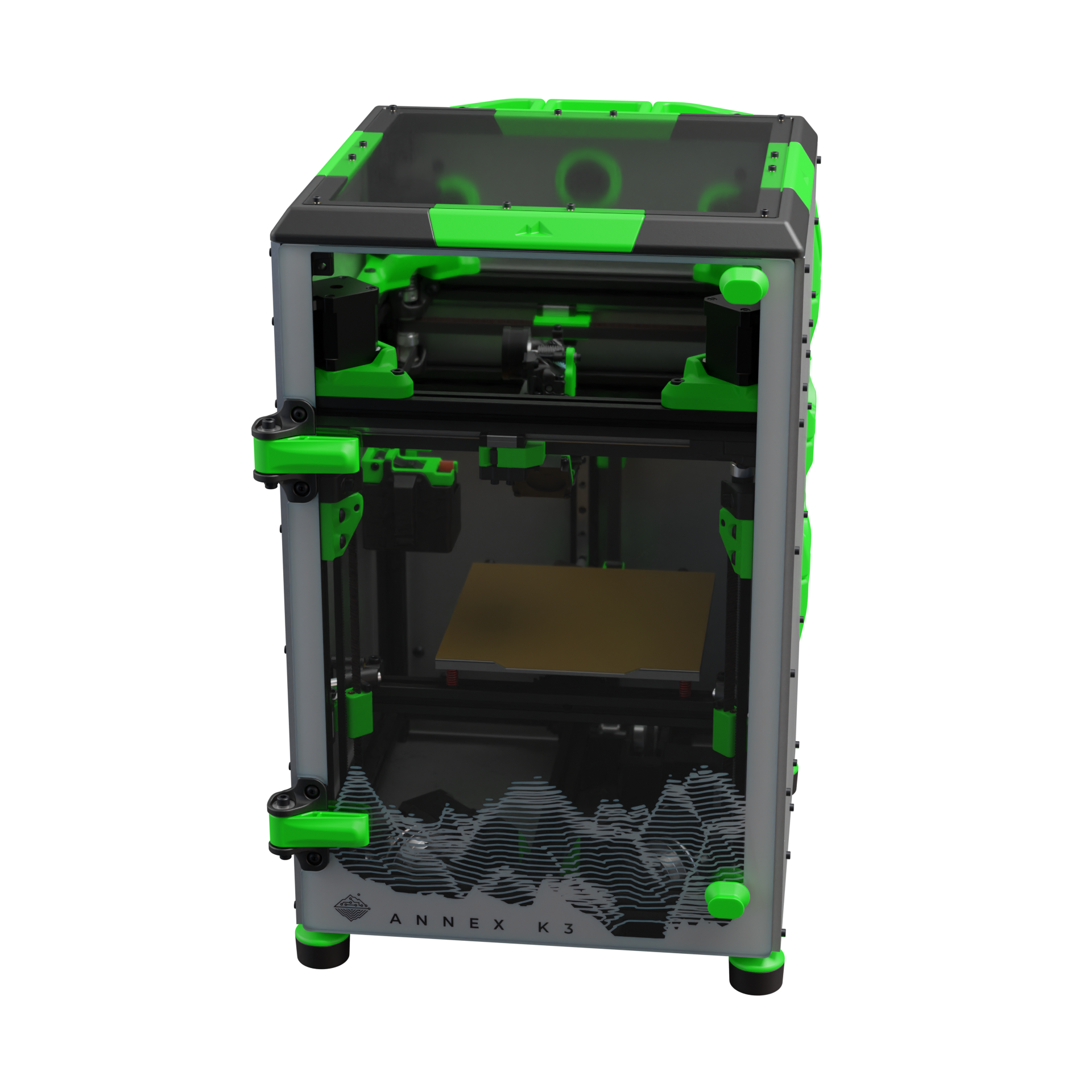

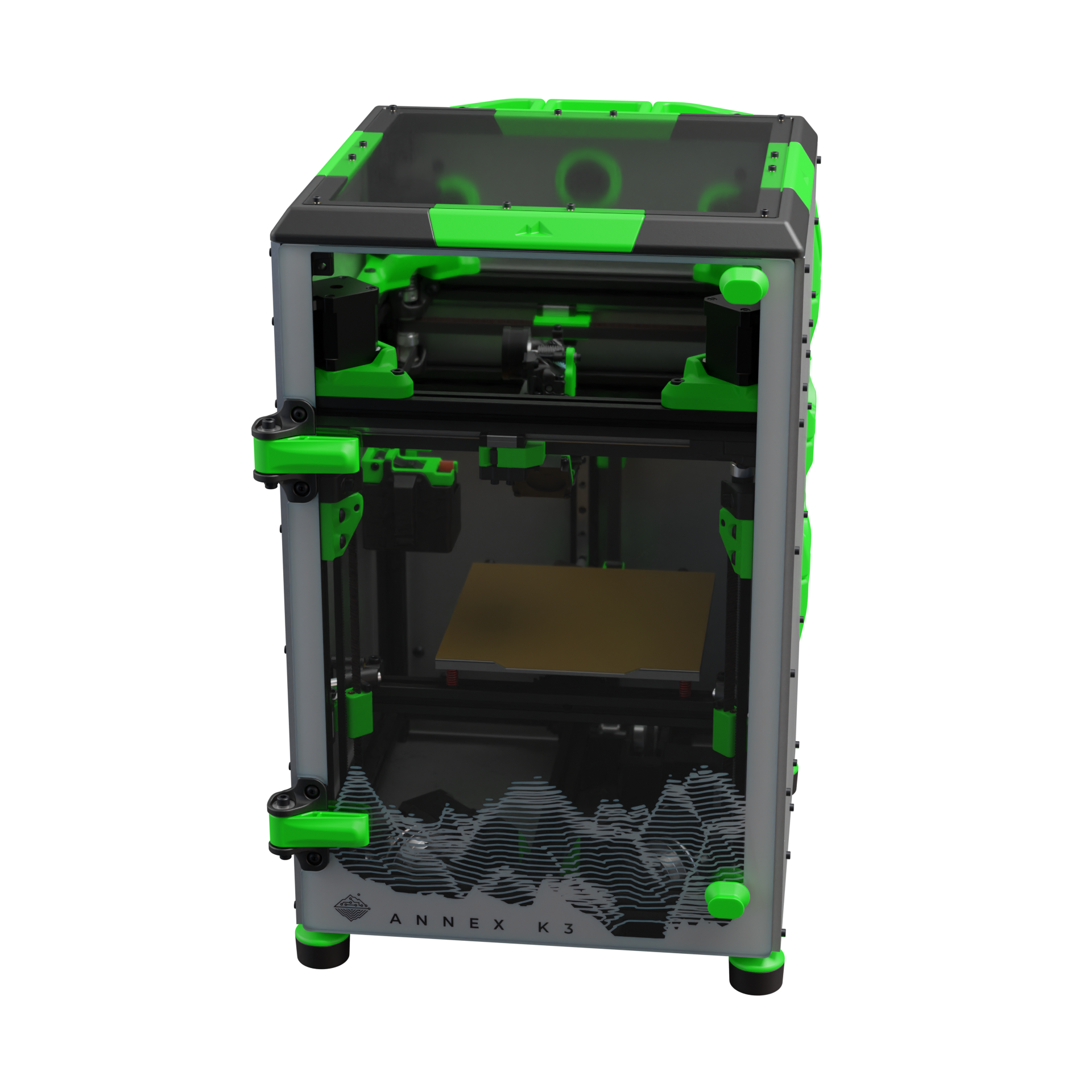

Annex Gasherbrum (K3) Printer

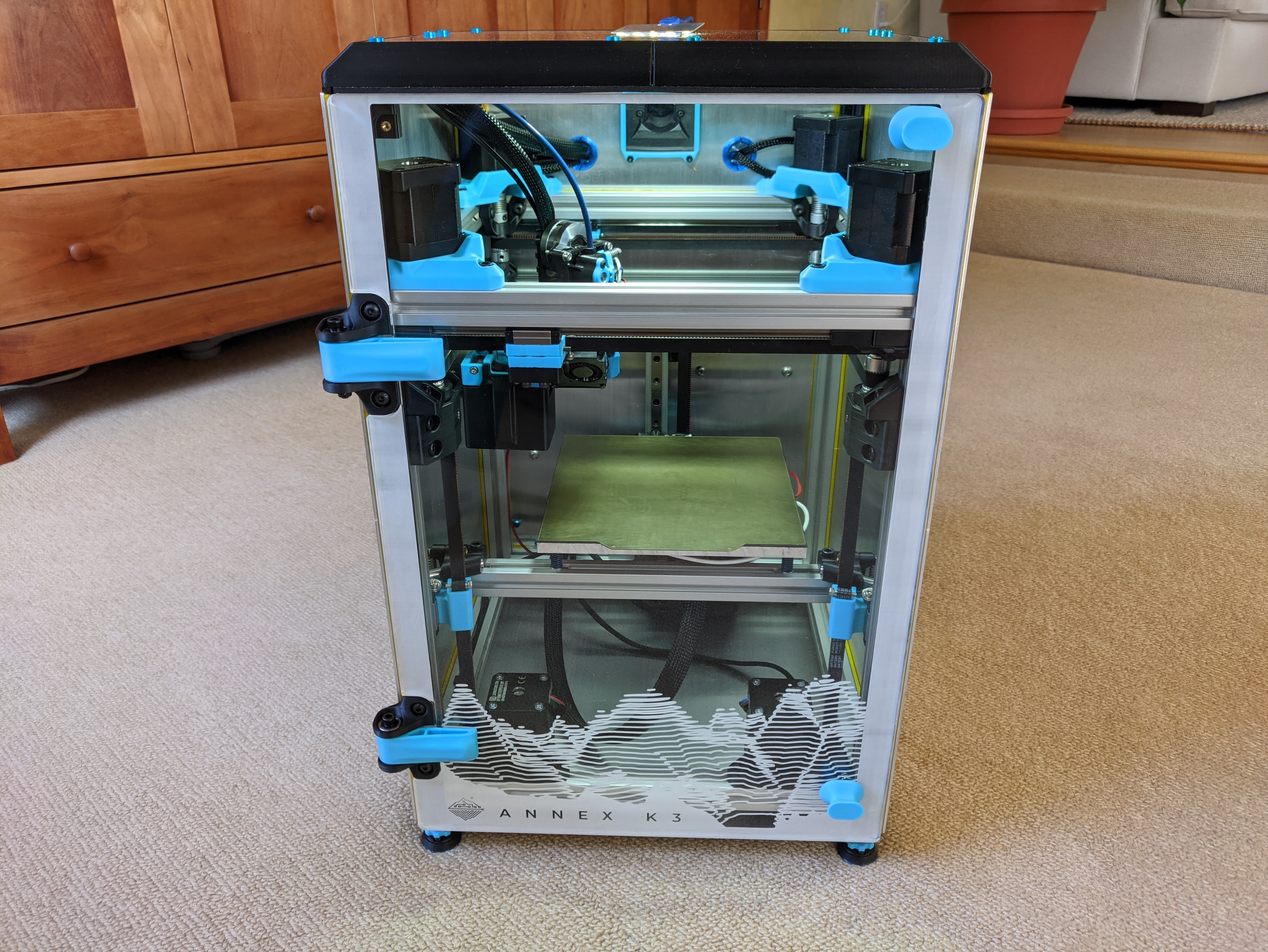

The K3 is an open source 3D printer by Annex Engineering. The project focuses on speed while maintaining high print quality, with short belt paths and 4 motors for movement in the X and Y axes.

This page highlights my main contributions to the K3 printer as a member of the Annex Engineering dev team.

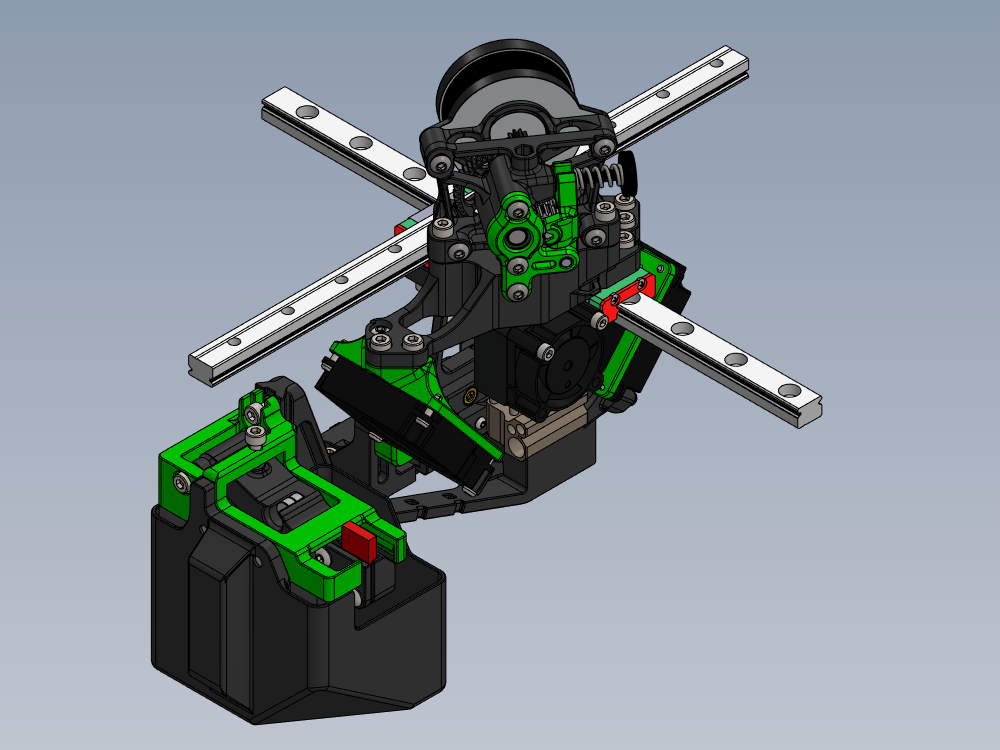

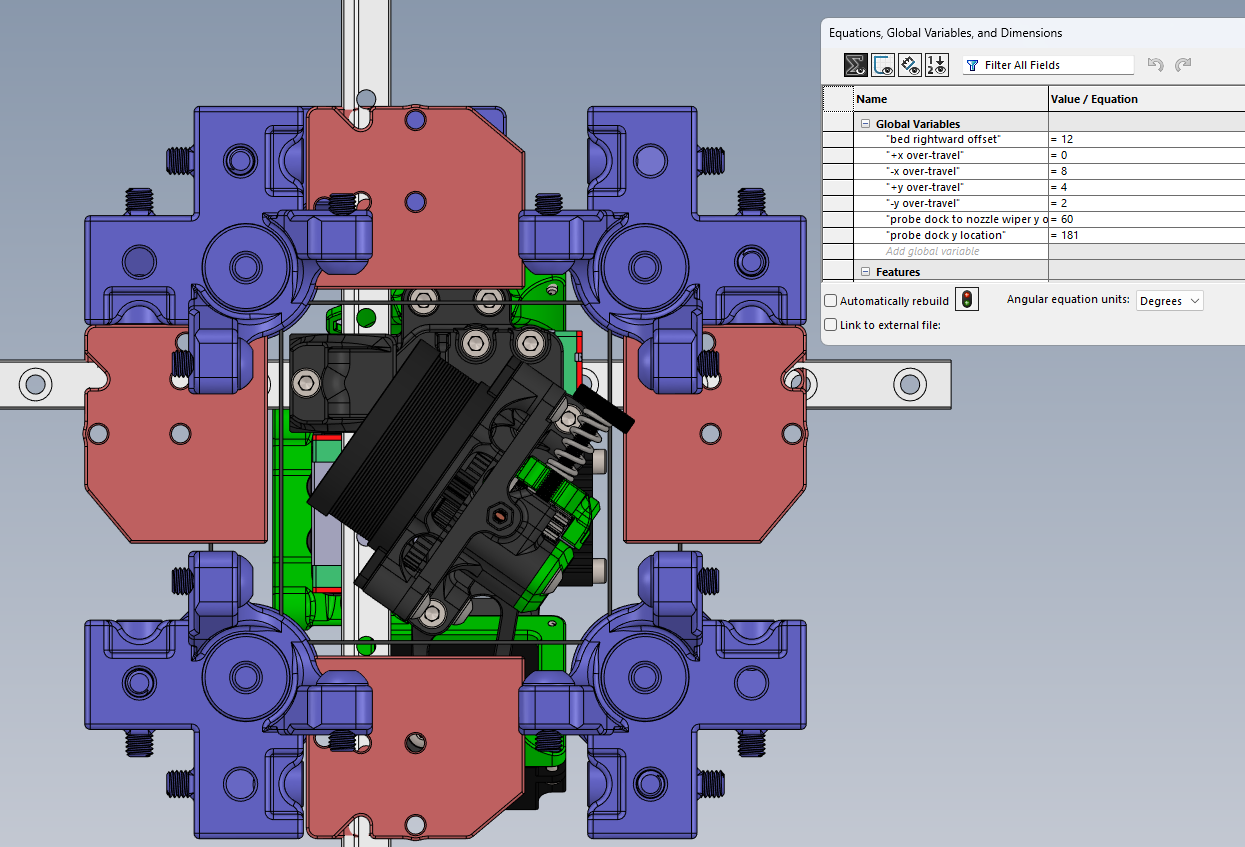

Toolhead Collision Checker

When I joined the K3 project as a beta tester, the toolhead design had not been finalized yet. The team had the following objectives:

- Add a second part cooling fan

- Add support for the Quickdraw probe

- Add support for the Sherpa Mini extruder

The main difficulty in adding these features to the toolhead was getting everything to fit in the limited space we had.

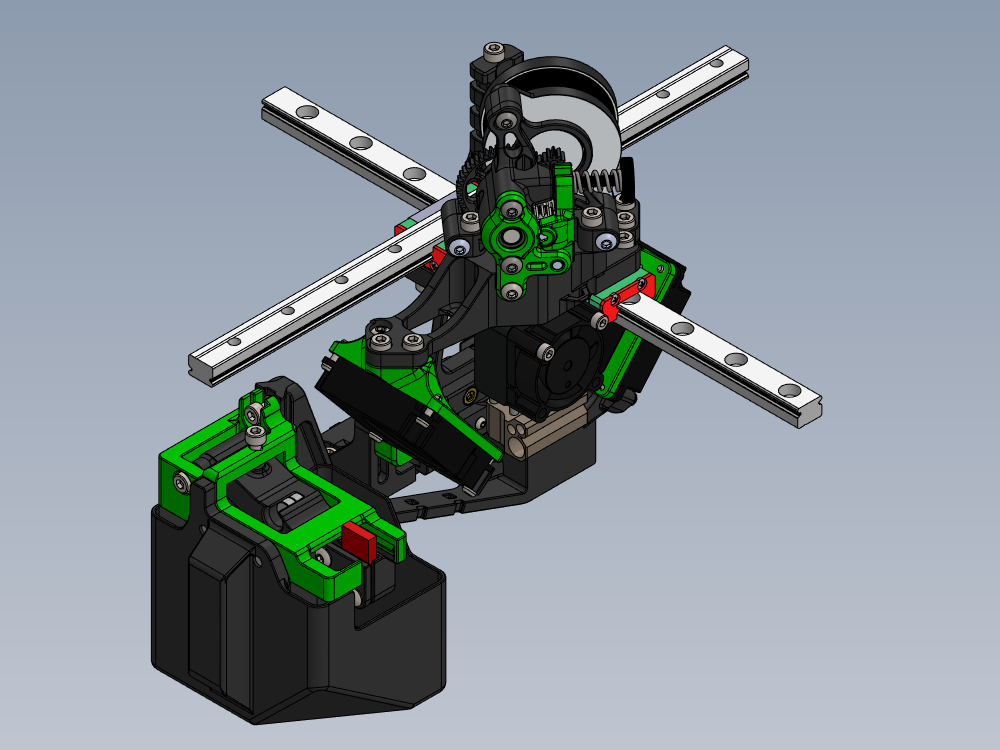

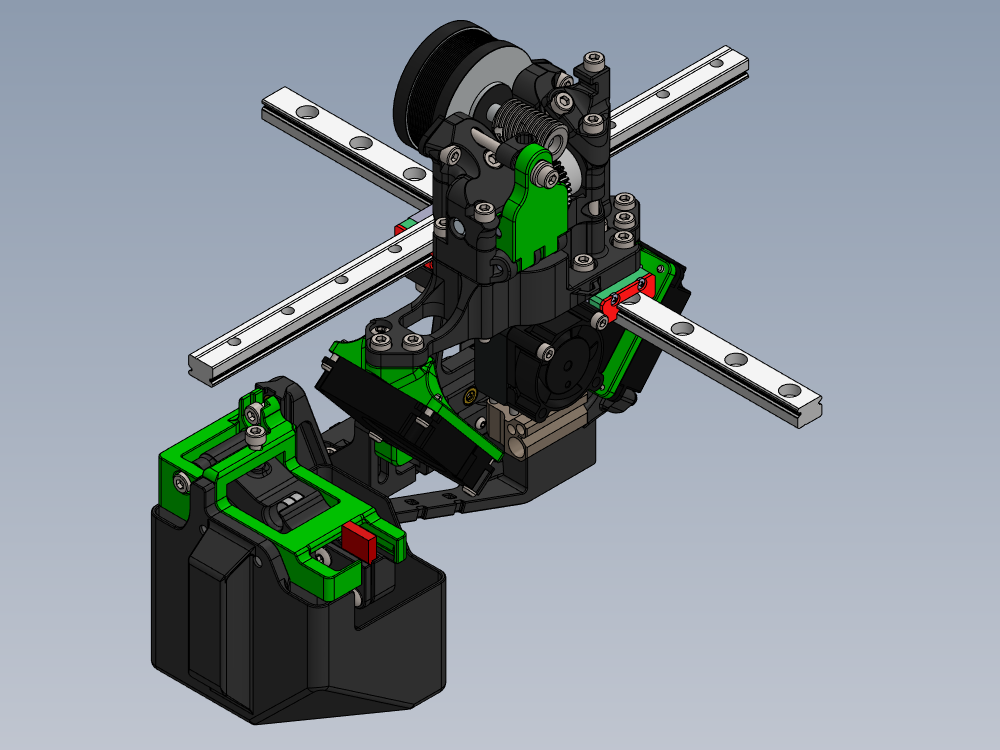

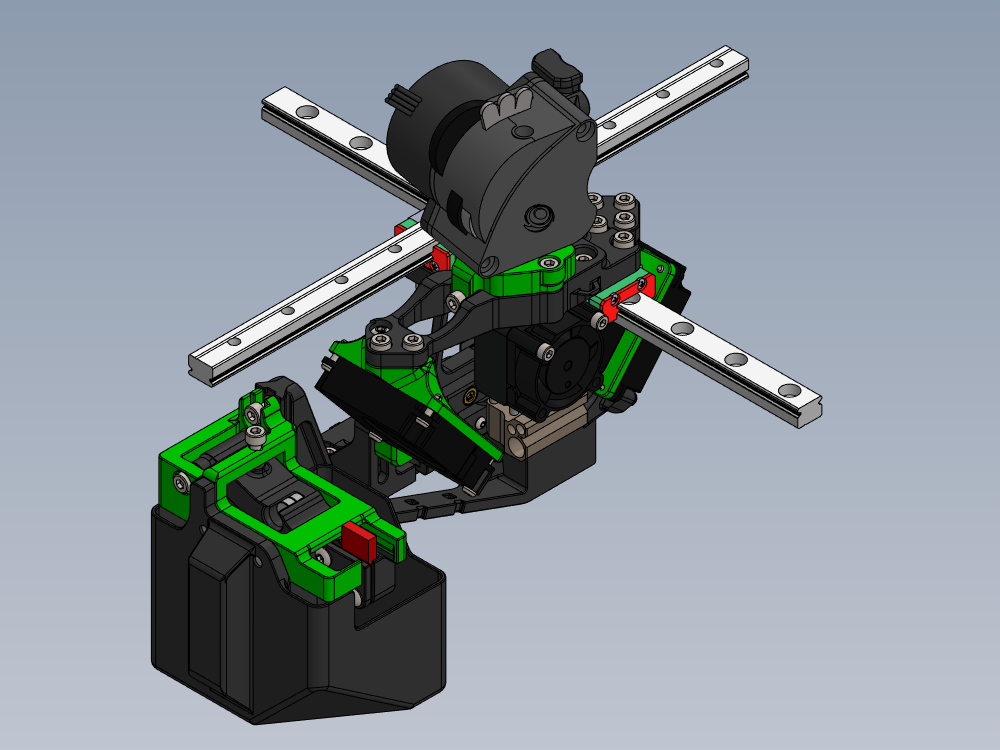

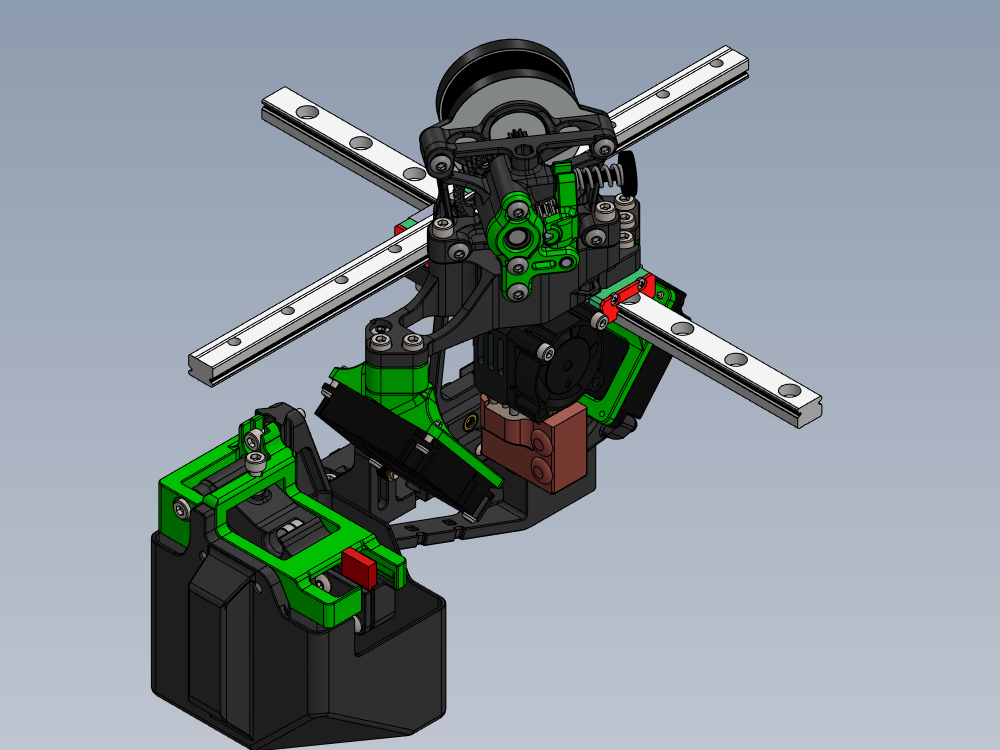

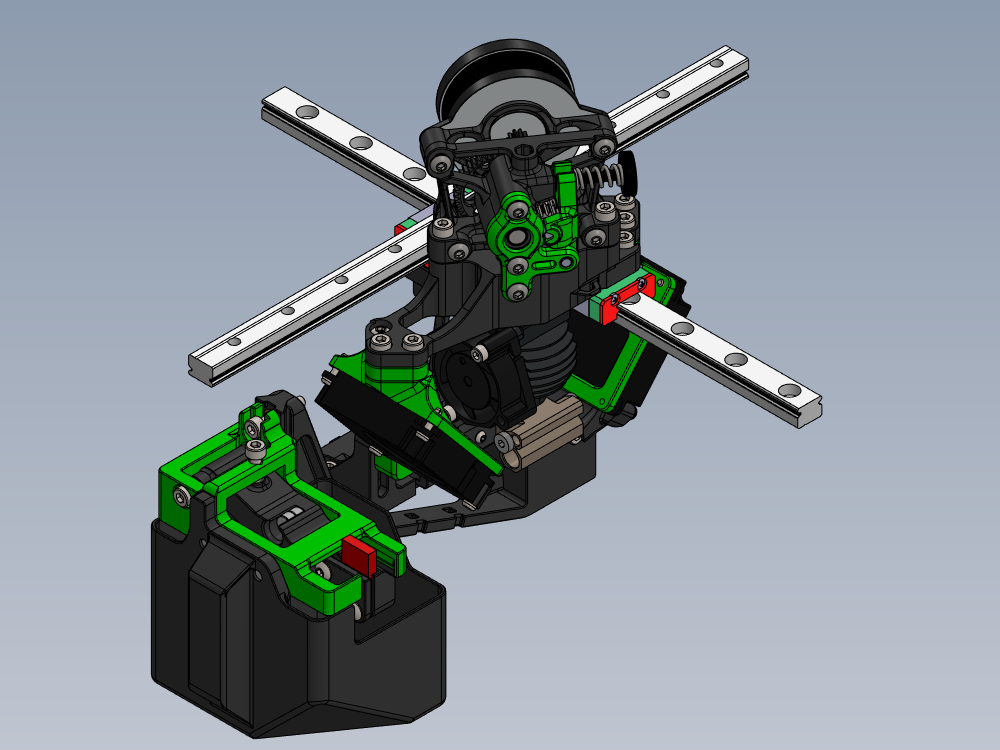

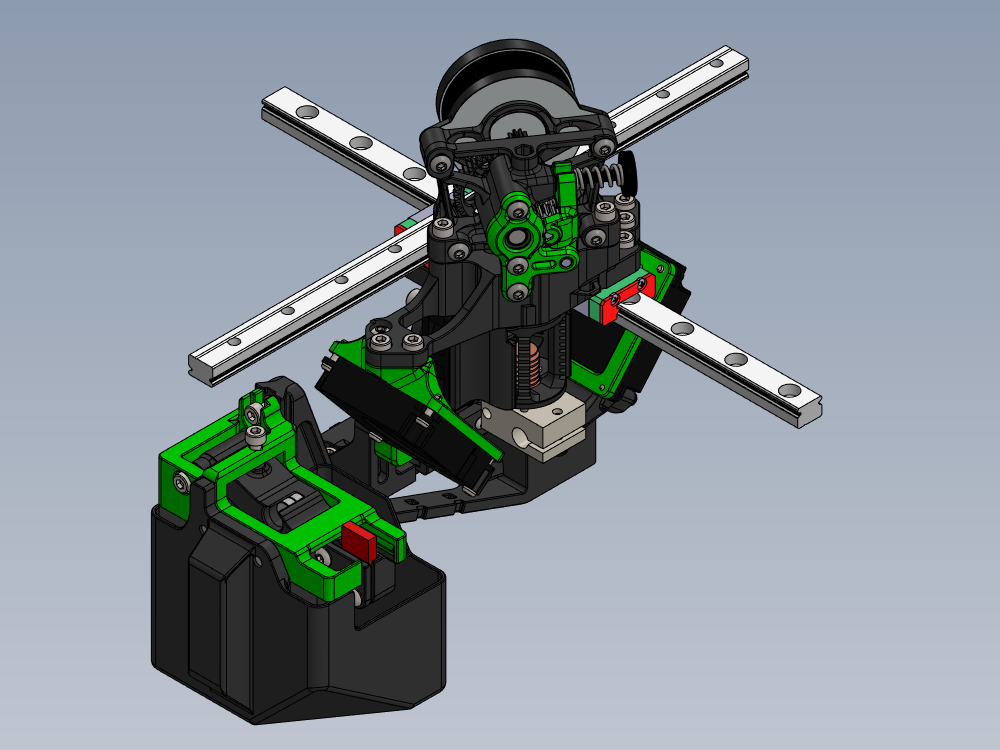

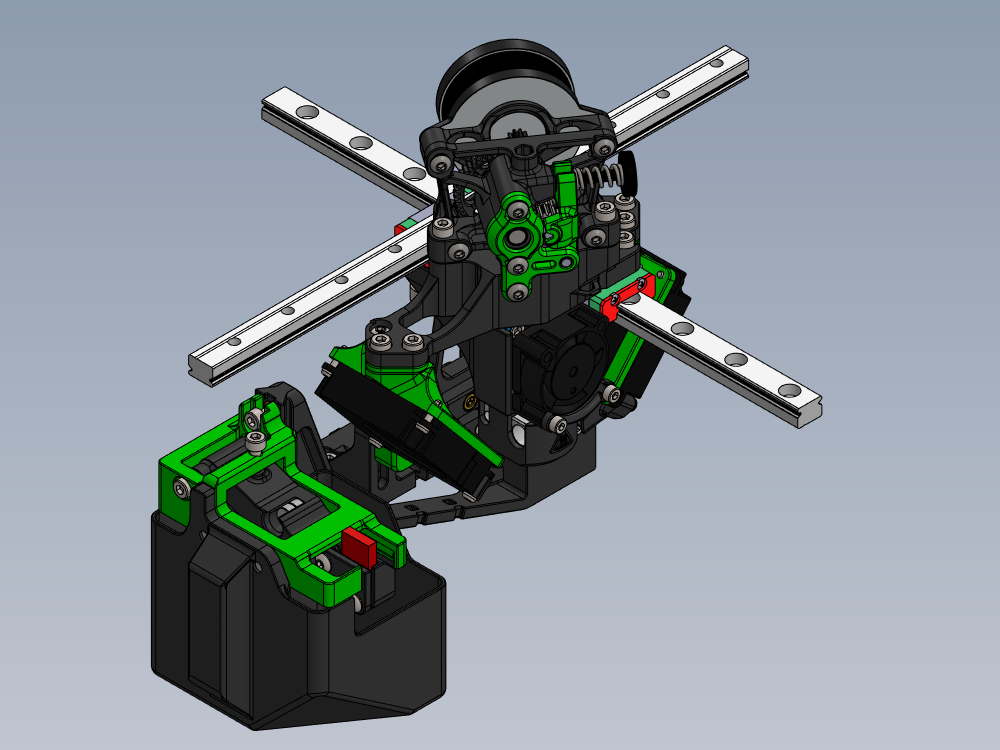

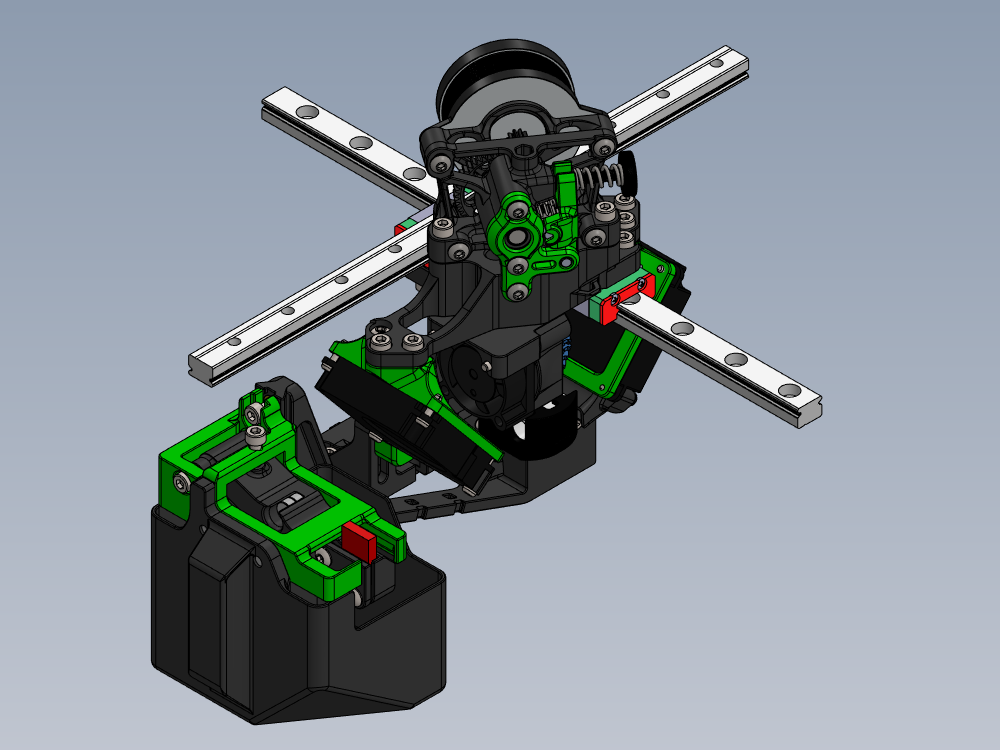

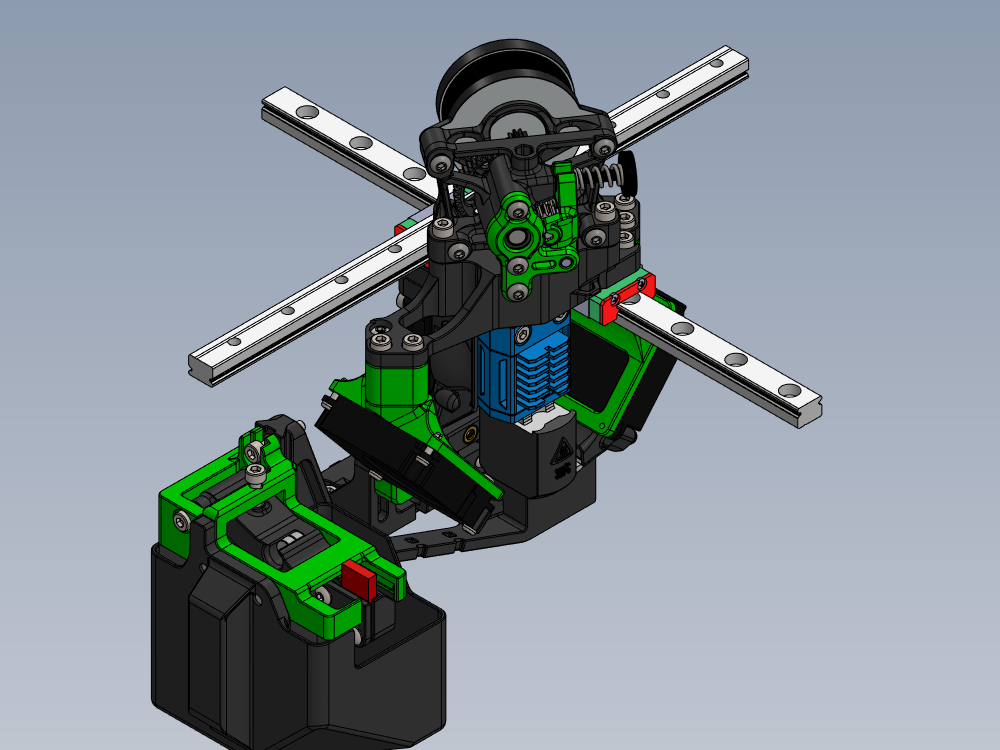

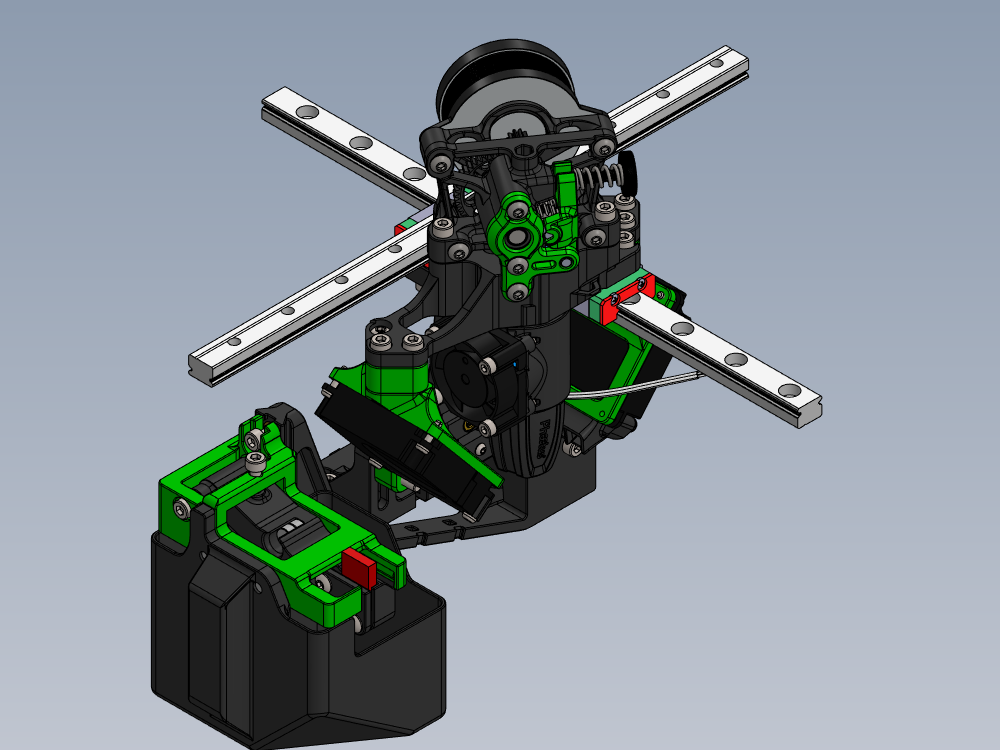

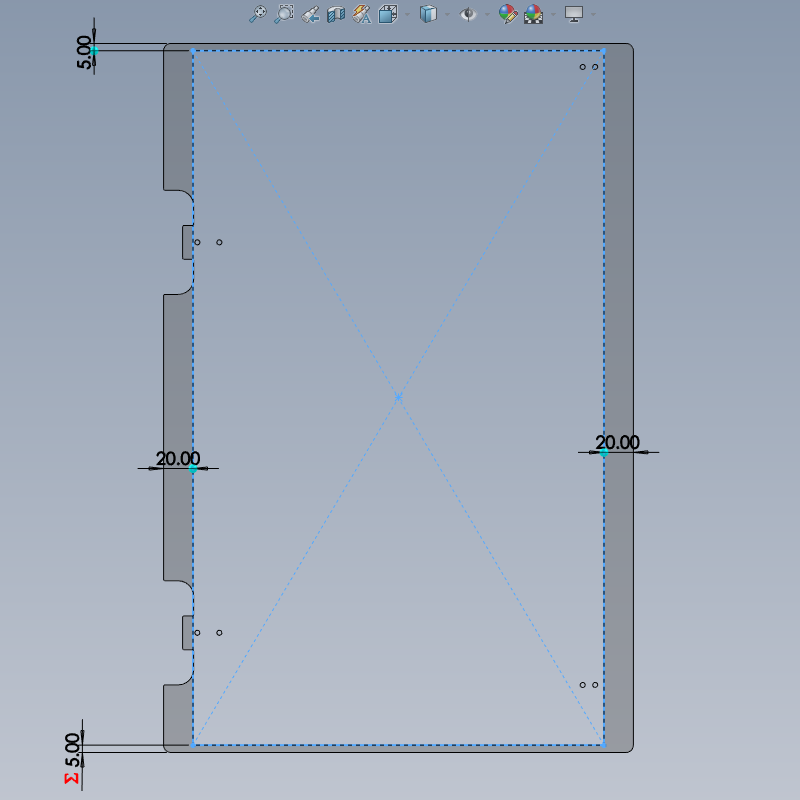

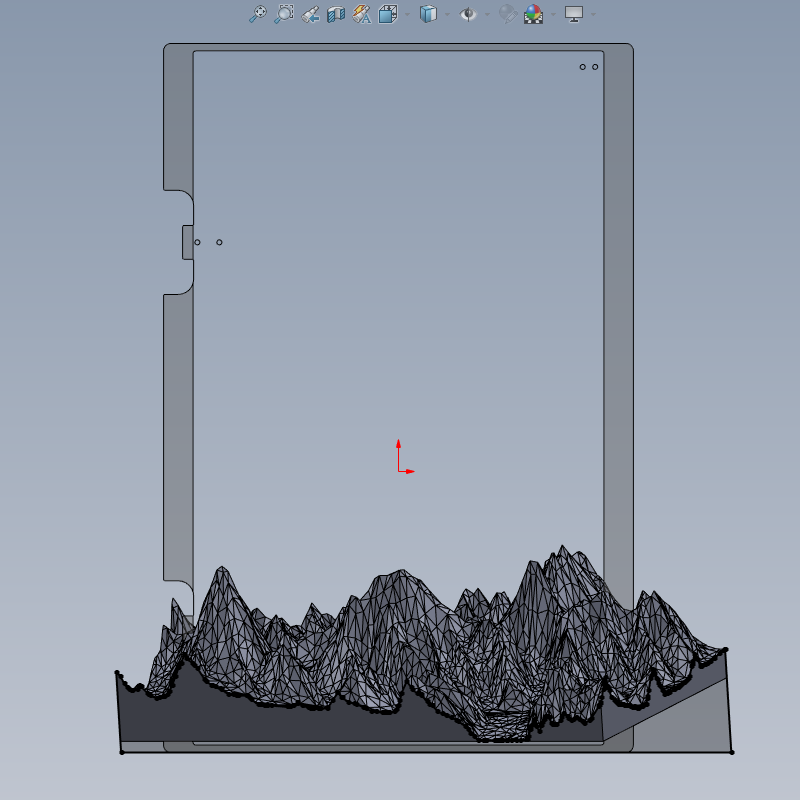

My first contribution was to make a collision-checking assembly in SolidWorks to define the allowable space envelope for the toolhead. This assembly brings all of the objects that could cause toolhead collision as close to the toolhead as they will get. Rather than modeling the toolhead and then moving it to the min and max positions on each axis to check for collisions on each side, all possible collisions can be visualized at once during design. I used global variables to define the position of the bed relative to the printer frame and the “over-travel” in each direction (how far the nozzle will move beyond each edge of the print bed). With the assembly parameterized, all the objects the toolhead might collide with are re-positioned automatically whenever any of the variables are changed. The image below shows the toolhead collision checker assembly with my toolhead design inserted.

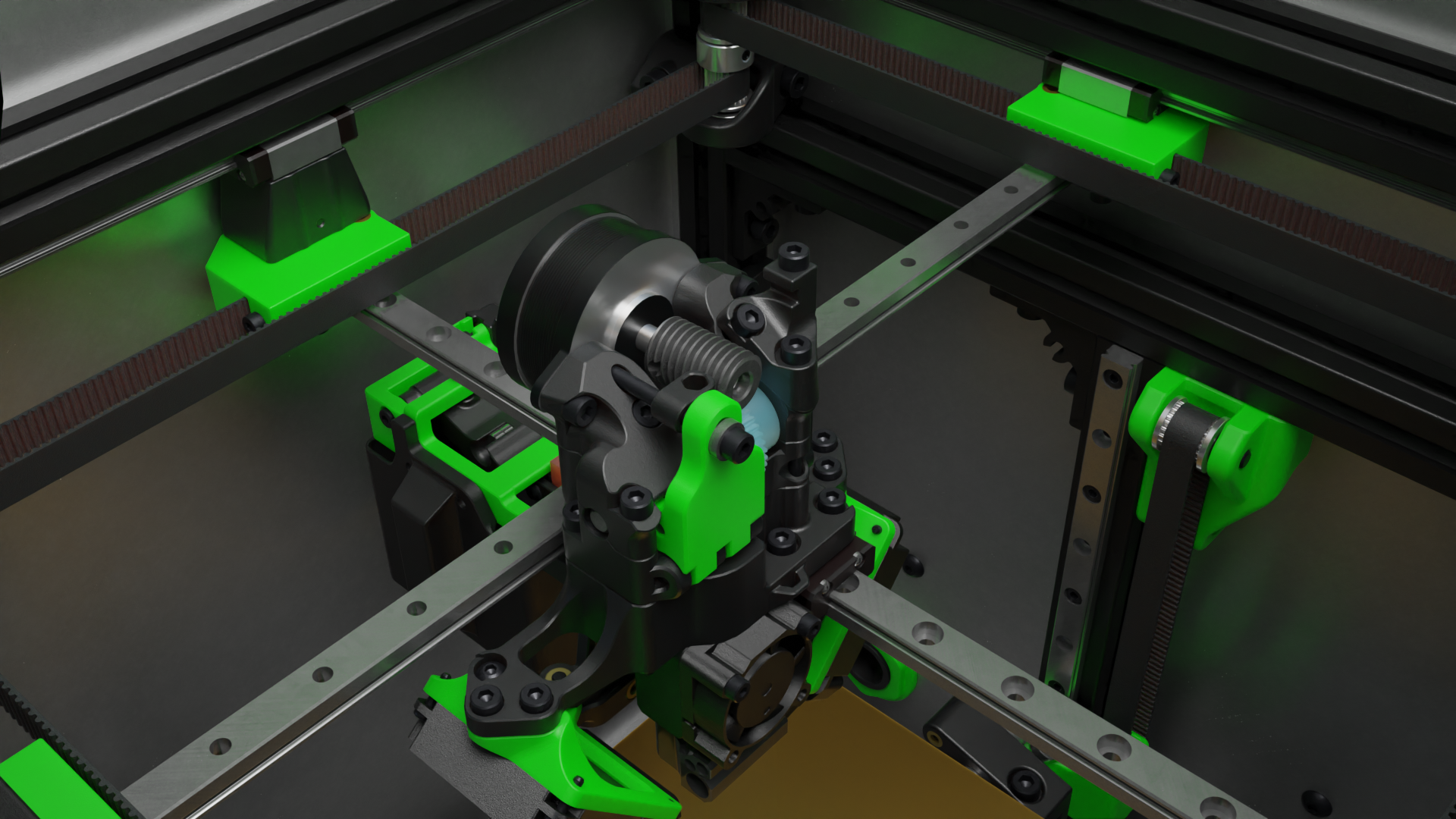

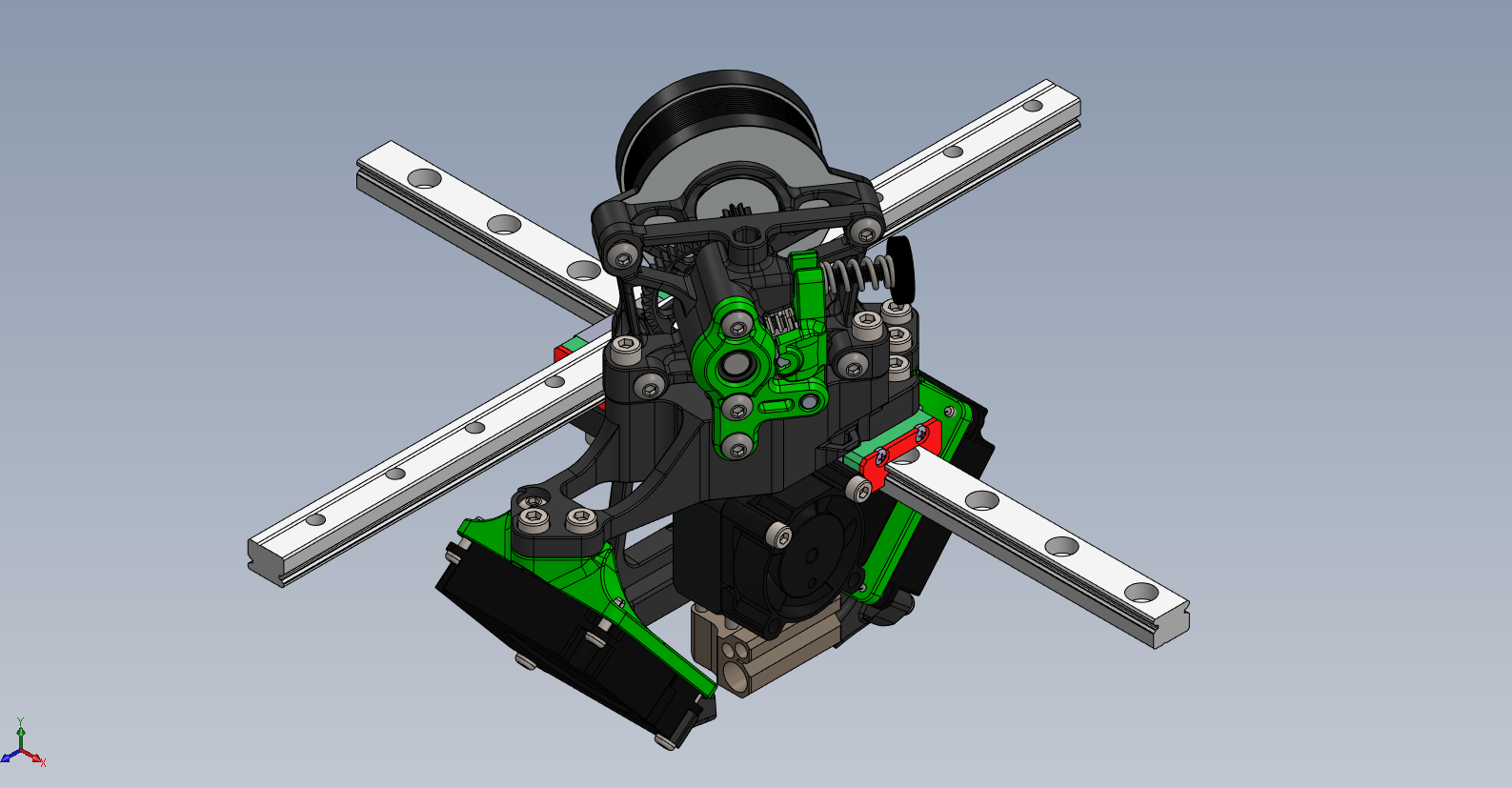

Toolhead

Utilizing my collision checker assembly, I designed a new toolhead for the K3 printer to accomplish all three objectives. I was added to the Annex Engineering dev team, and my design became the official toolhead for the K3 printer.

I later added additional configurations to the toolhead to support more extruder and hotend options.

The video below shows a K3 printer doing a print, running the Ascender/Mosquito variant of the toolhead:

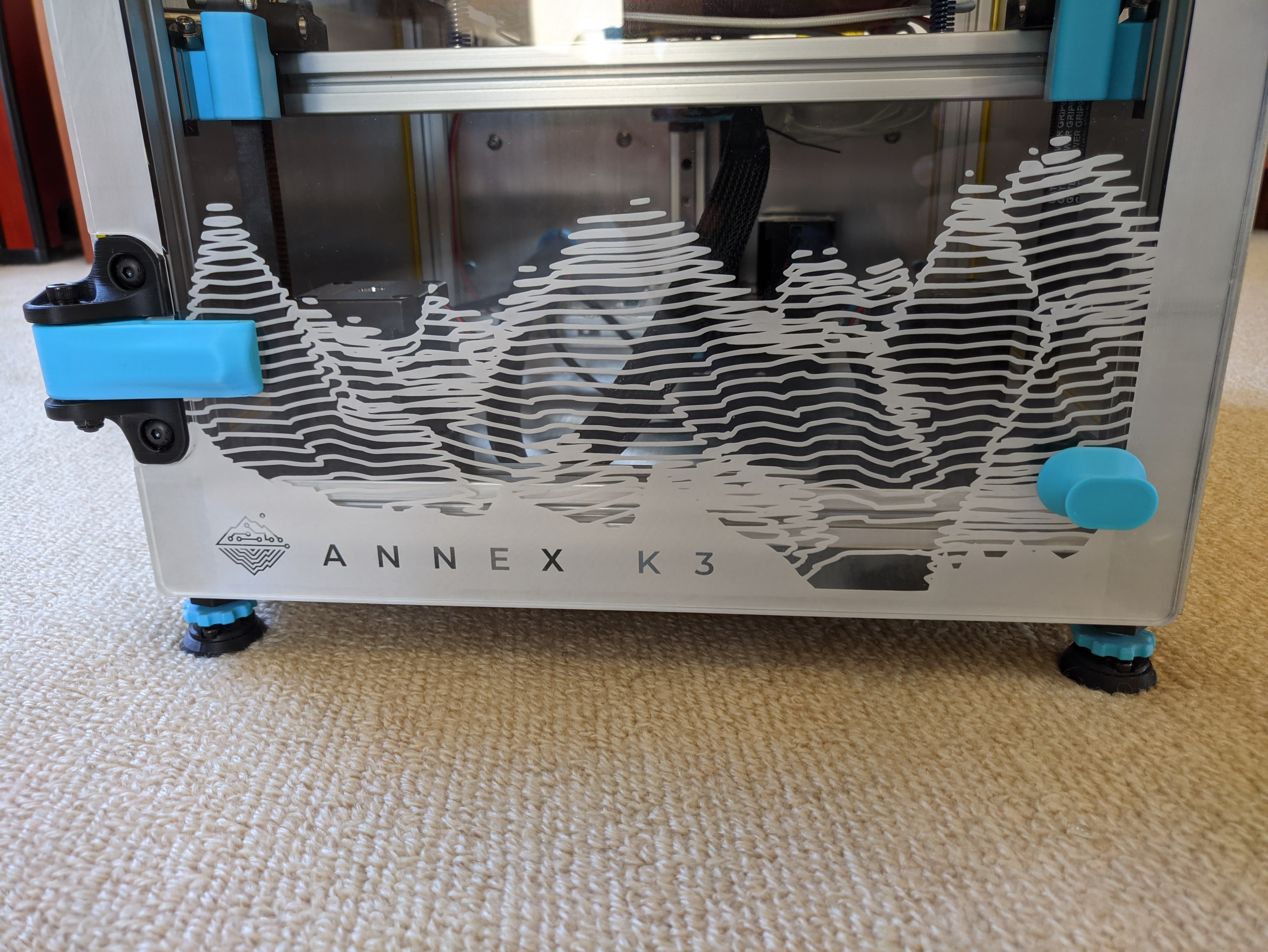

Front Door Engraving

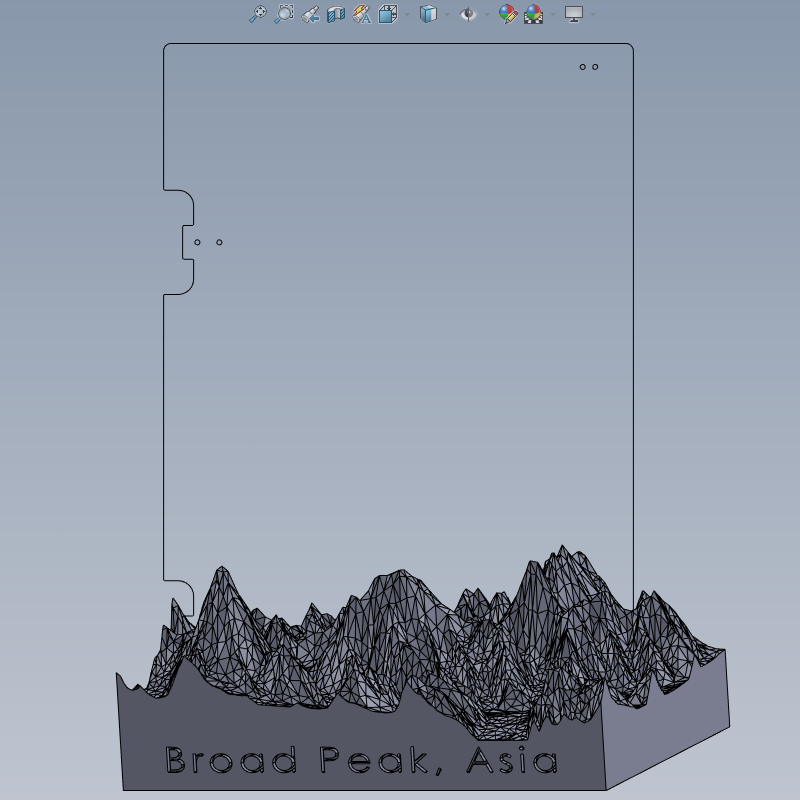

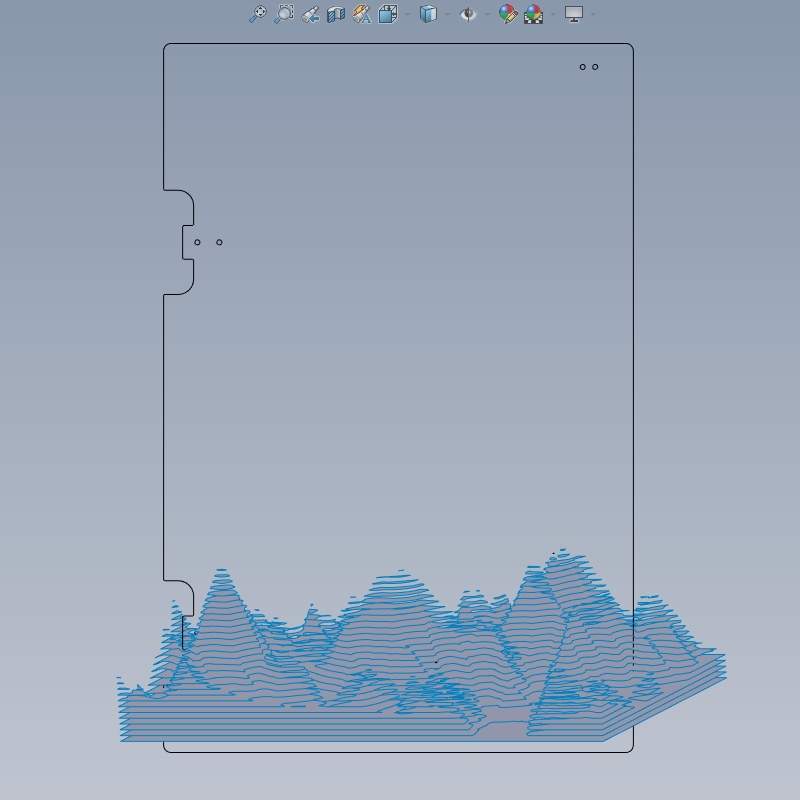

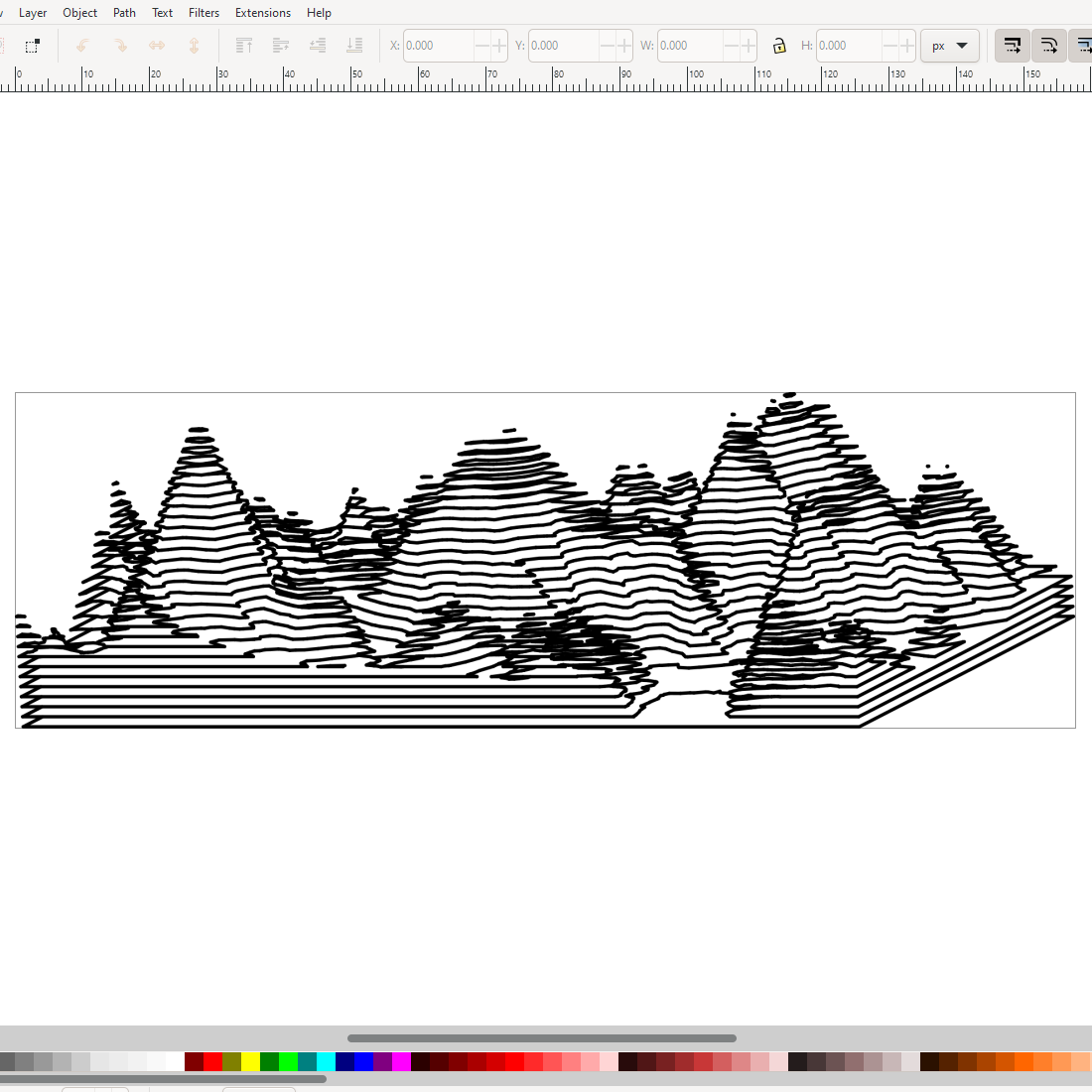

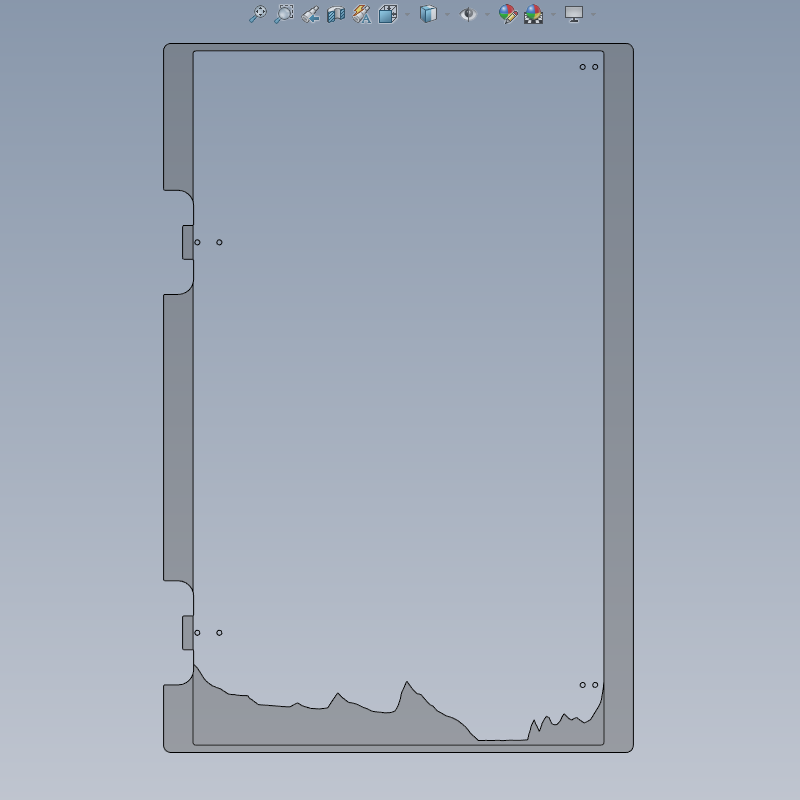

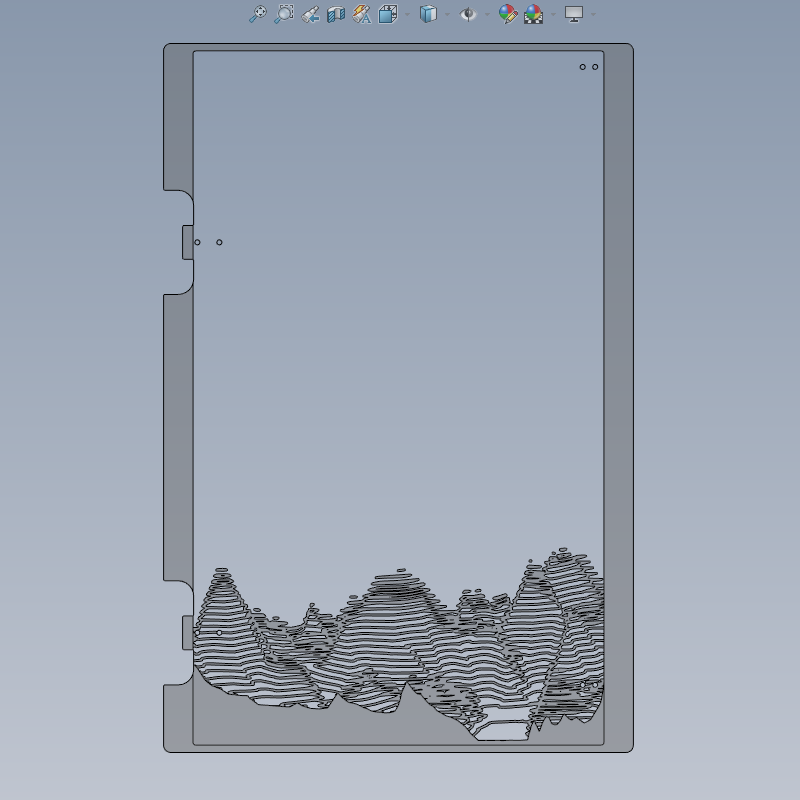

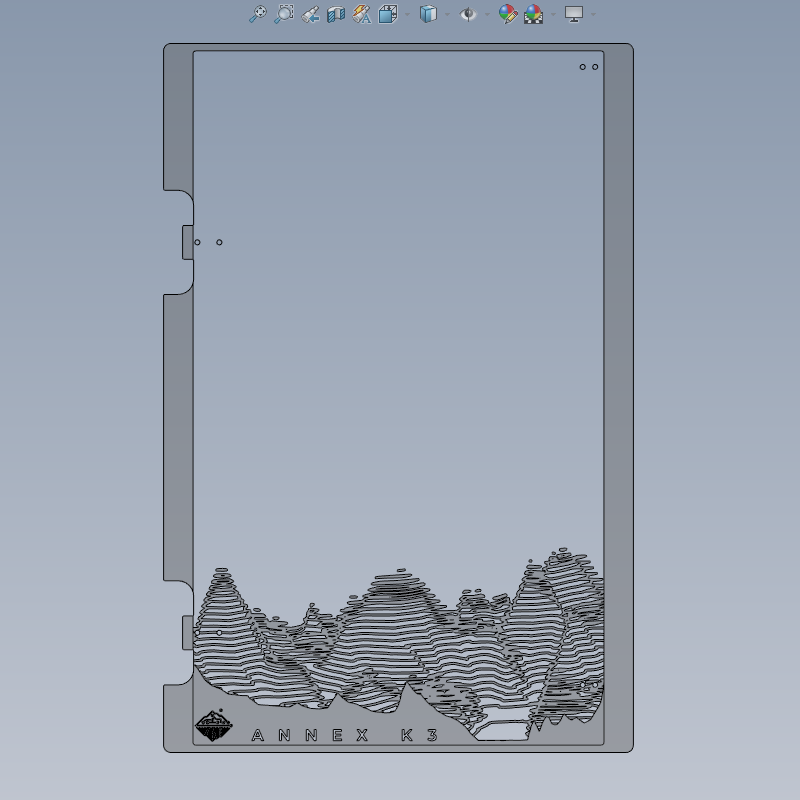

I designed the mountain graphic for K3’s front door using SolidWorks and Inkscape. Just like Annex’s larger K2 printer, the graphic is derived from a 3D model of the mountain that the printer is named after.

The final result is shown below:

The steps I used to create the graphic are shown below. I used SolidWorks to create the “slices” from the mountain 3D model and to add the outline and text, and I used Inkscape to add thickness to the mountain slice edges.

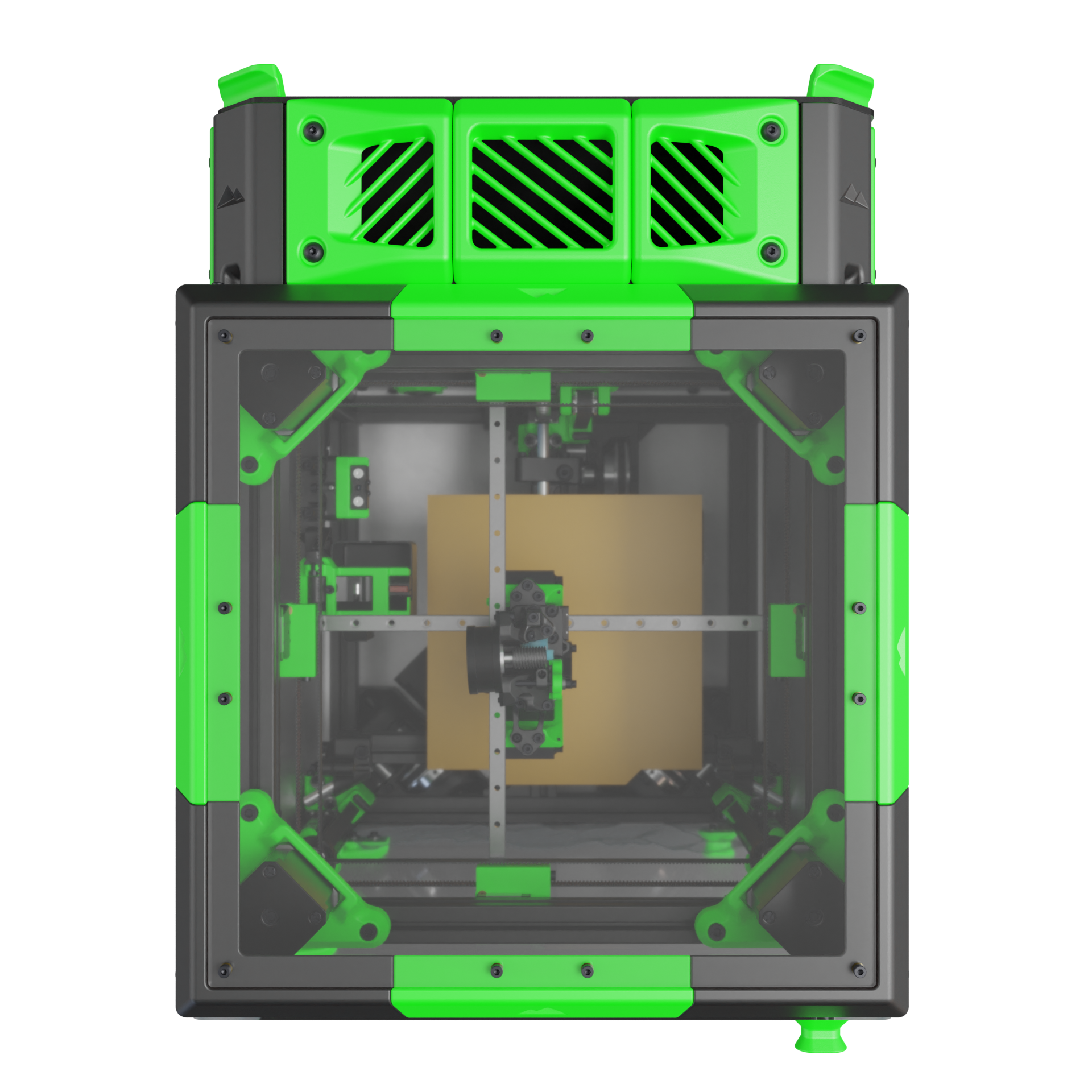

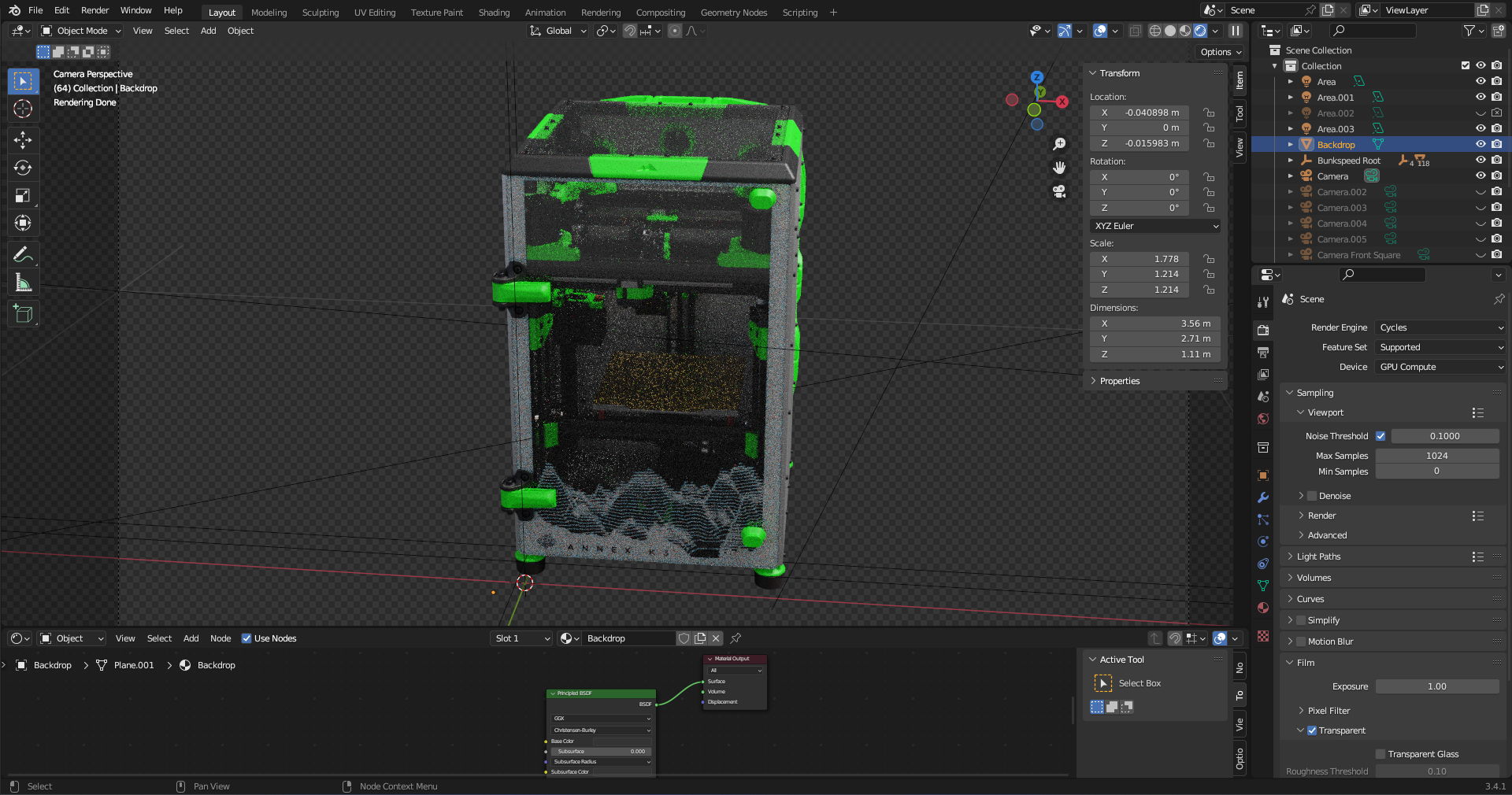

Renders

I created renders for the K3 printer using Blender. These renders were used in the project readme and in Fabreeko product listings.

The renders are shown below: